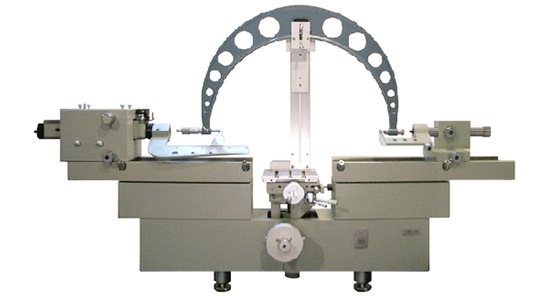

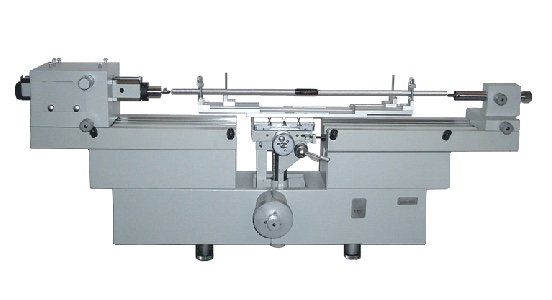

Long Gage Blocks calibration

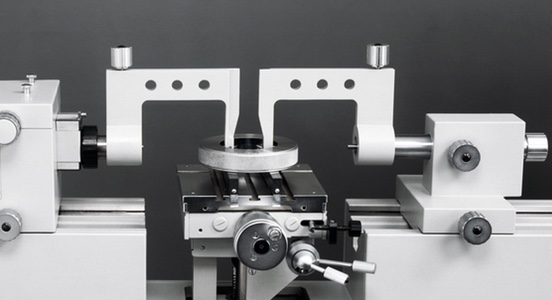

A special table holds the gage blocks on the Airy's points.

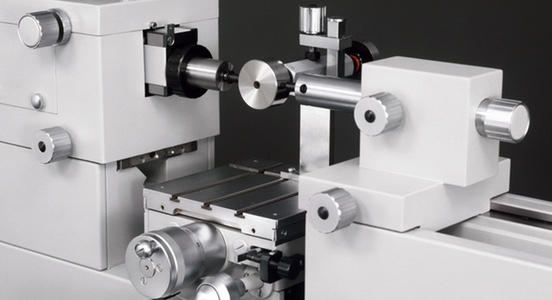

Inspection of plain plug and plain ring gage.

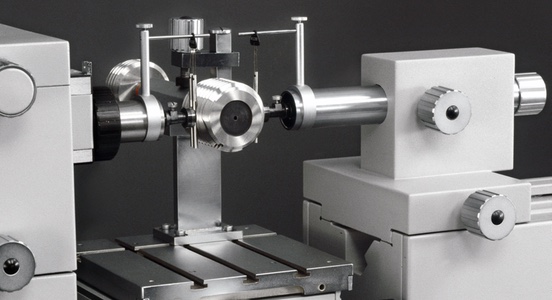

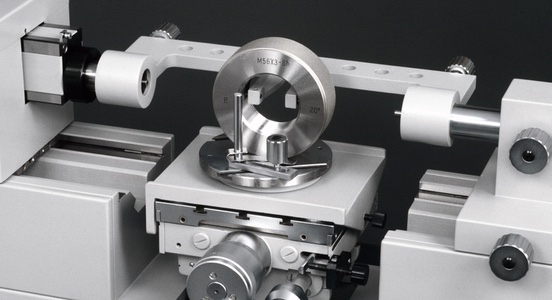

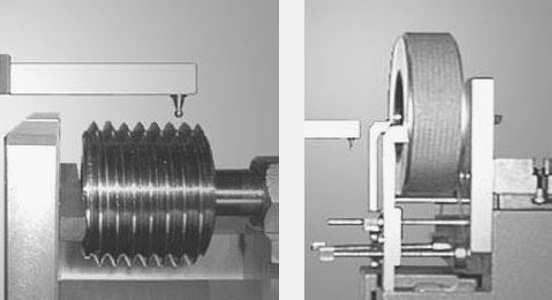

Inspection of thread plug, thread ring and pipe thread gage.

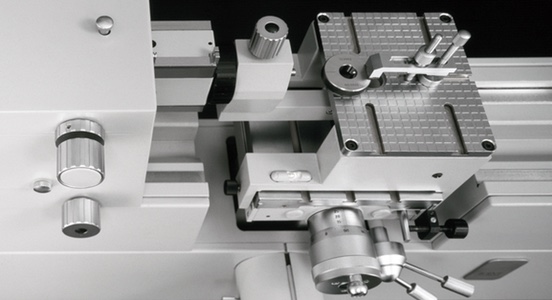

Inspection of internal and external spline gage.

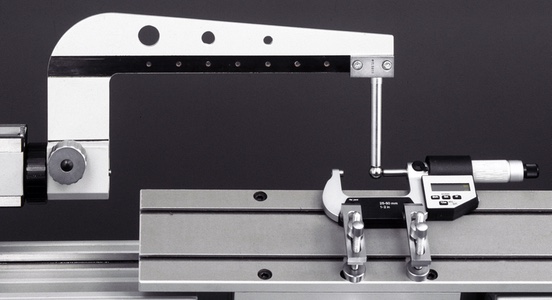

Inspection of indicator, lever type indicator, micrometer and bore gage.

A special table holds the gage blocks on the Airy's points.

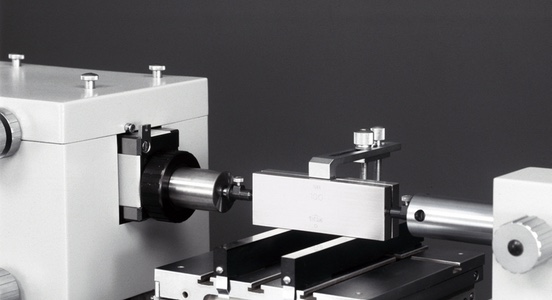

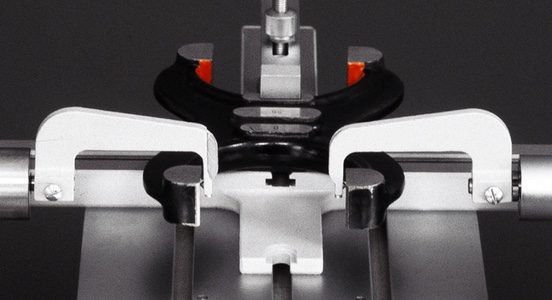

A special "V" table holds the gage

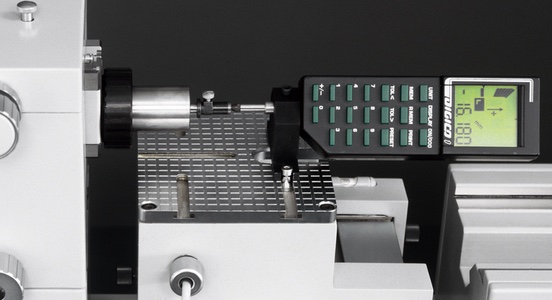

The movements of the work table enables high speed location of the inversion point.

Three wire method. Calibrated wires are part of the equipment included with the machine.

The inspection is carried out by comparison with master gage block.

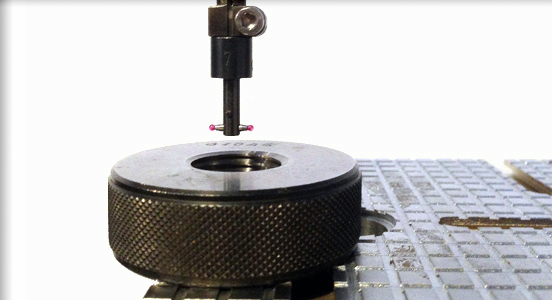

Plain ring inspection.

The standard device includes 12 pairs of spheres for internal thread measurement. Range: 14-90 mm | 0.5"-3.5"

The measurement is carried out with zero contact force.

Minimum diameter: 1mm | 0.04".

Snap gages are placed on a special holder.

Micrometer head verification.

Inspection of digital comparator, dial indicator and lever type probe.

Standard included in the price, the temperature compensation device allows to:

The device allows to measure thread ring down to 3 mm - 0.12". Working field: 3-90 mm | 0.12"-3.5".

Internal and External thread pitch verification.

The lever probe with sphere-stylus allows to measure small plain ring gage. A manual system (small ring device) is part of the standard accessories.

To extend measurement range of thread ring gages up to 400 mm | 16"

Optional extra weights to change the measurement force.

Gage with involute profile inspection.

| external plan | 0 - 1000 mm | 0 - 40 " |

|---|---|---|

| internal plan | 0 - 480 mm | 0.04 - 19 " |

| external thread | 0 - 480 mm | 0 - 19 " |

| internal thread | 3 - 400 mm | 0.12 - 16 " |

| absolute | 100 mm | 4 " |

|---|---|---|

| differential | 1000 mm | 40 " |

DMS 1000

3 Mb

Version: 1.0 | date: 2016

Temperature compensation leaflet

150 Kb

Version: 1.0 | date: 2016

Languages

MicroNet software catalogue

800 Kb

Version: 1.0 | date: 2016

Languages