Specifications

Operating system: Windows 10 (other on request).

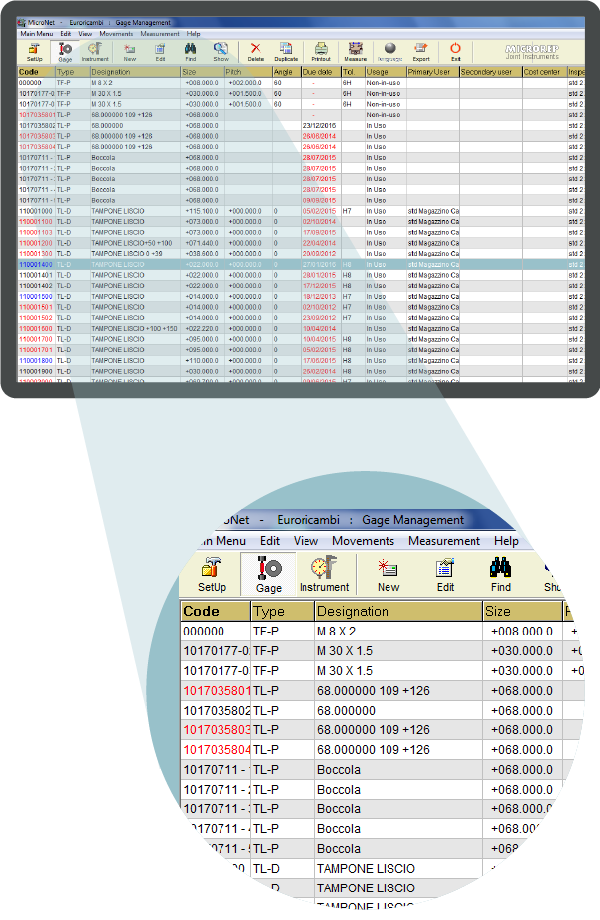

Network environment: MicroNet software works in network environment (addition licenses required).

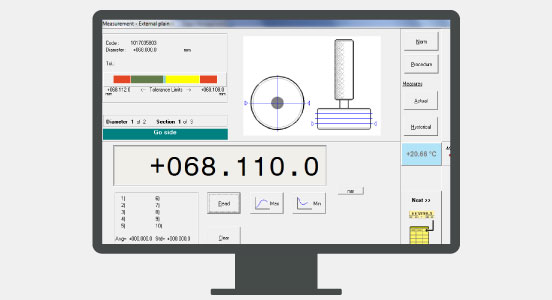

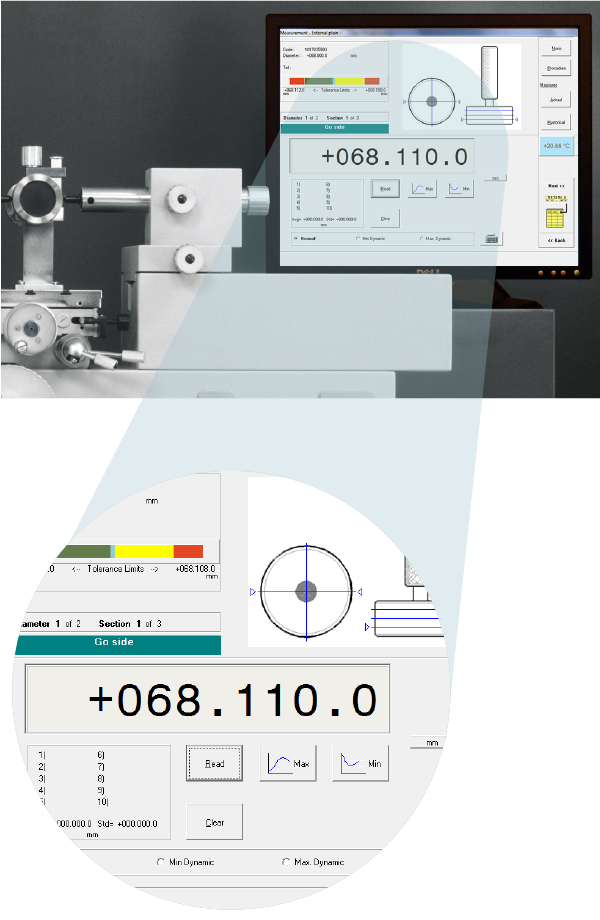

Data Acquisition:

- Universal length measuring system Joint Instrument DMS 680

- Universal length measuring system ULM 600 and other devices

- RS-232 (enquire for driver availability)

- keyboard

Documentations and printout:

- Automated calibration certificate printout.

- Certificates output directly into Excel format.

- Export in different file format: Excel (xls), Acrobat Reader (pdf), etc.

Norms and Standards: Tolerance calculation according to ISO/R - 1938, ISO 261, ISO 262, ISO 286, SO 965/1, ISO/R 1502, ANSI/ASME B1.13M, ISO 965/1, ANSI/ASME B1.16M-1984, ANSI/ASME B89.1.6M-1984, Gagemaker's Tolerance Chart, ANSI/ASME B.1.1-1982, ANSI/ASME B1.2-1983, ANSI/ASME B.1.20.1-1983, ASME B1.20.5-1991, ISO 228, ISO 7, DIN 5480, BS 919, BS 84, ANSI B1.9, BS 1657, NF.E.02-202, etc. .

Integration: MicroNet software can be integrated with other software packages through SQL queries, etc.

Languages: software available in different languages (English, Italian, Spanish, Portuguese, French, German, Korean, Japanese, Chinese, Russian, Romanian, Danish, etc.)